Welded Steel Pipe

What is Welded Steel Pipe?

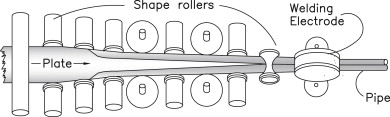

Welded steel pipe refers to the steel strip or steel plate bending deformation into circular, square and other shapes after welding, the surface of the joint steel pipe, welded steel pipe using steel plate or strip steel. According to different welding methods, welded steel pipe can be divided into arc welding pipe, high frequency or low frequency resistance welding pipe, gas welding pipe, furnace welding pipe, Bondi pipe and so on.

Welding steel pipe according to weld shape can be divided into straight seam welding pipe and spiral welding pipe. The advantages of direct seam welded pipe are simple production process, high production efficiency, low cost and rapid development. The advantage of spiral welded pipe is that the strength is higher than that of straight seam welded pipe, the welded pipe with larger diameter can be produced with narrower billet, and the welded pipe with different diameter can be produced with the same width blank. But compared with the straight seam pipe of the same length, the weld length is increased by 30~100%, and the production speed is lower. Therefore, the smaller diameter welded pipe mostly adopts direct seam welding, and the large diameter welded pipe mostly adopts spiral welding. Spiral welded steel pipe can be divided into automatic submerged arc welded steel pipe and high frequency welded steel pipe according to welding technology.

According to the purpose of welding steel pipe can be divided into general welding pipe, galvanized welding pipe, oxygen blowing welding pipe, wire casing, metric welding pipe, roller pipe, deep well pump pipe, automobile pipe, transformer pipe, welding thin wall pipe, welding special-shaped pipe and spiral welding pipe. Welded steel pipe according to end shape can be divided into circular welded pipe and irregular (square, flat, etc.) welded pipe.

| Standard, Application of Welded Steel Pipe | ||

| S.N. | Standards | Application |

| 1 | ASTM A134 | Electric-Fusion (Arc)-Welded (Sizes NPS 16 and Over) Steel Pipe |

| 2 | ASTM A135 | Electric-resistance-welded(ERW) steel pipe in NPS 2 to NPS 30 |

| 3 | ASTM A139 | Electric-Fusion (Arc)-Welded Steel Pipe (NPS 4 and Over) |

| 4 | ASTM A178 | Electric-Resistance-Welded(ERW) Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes |

| 5 | ASTM A214 | Electric-Resistance-Welded(ERW) Carbon Steel Heat-Exchangerand Condenser Tubes |

| 6 | ASTM A250 | Electric-Resistance-Welded(ERW) Ferritic Alloy-Steel Boiler and Superheater Tubes |

| 7 | ASTM A252 | Welded and Seamless Steel Pipe Piles |

| 8 | ASTM A333 | Seamless and Welded Steel Pipe for Low Temperature Service |

| 9 | ASTM A334 | Seamless and Welded Carbon and Alloy Steel Tubes for Low Temperature Service |

| 10 | ASTM A381 | Metal-Arc-Welded Steel Pipe for Use With High-Pressure Transmission Systems |

| 11 | ASTM A500 | Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes |

| 12 | ASTM A501 | Hot-Formed Welded and Seamless Carbon Steel Structural Tubing |

| 13 | ASTM A513 | Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing |

| 14 | ASTM A523 | Plain end Seamless and Electric Resistance Welded Steel Pipe for High Pressure Pipe Type Cable Circuits |

| 15 | ASTM A53 | Seamless and Welded Black and Hot-dipped Galvanized Steel Pipe |

| 16 | ASTM A618 | Hot-Formed Welded and Seamless High-Strength Low-Alloy Structural Tubing |

| 17 | ASTM A671 | Electric-Fusion-Welded Steel Pipe for Atmospheric and Lower Temperatures |

| 18 | ASTM A672 | Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures |

| 19 | ASTM A691 | Carbon and Alloy Steel Pipe Electric-Fusion-Welded for High-Pressure Service at High Temperatures |

| 20 | ASTM A714 | High Strength Low Alloy Welded and Seamless Steel Pipe |

| 21 | ASTM A795 | Black and Hot-Dipped Zinc-Coated (Galvanized) Welded and Seamless Steel Pipe for Fire Protection Use |

| 22 | EN 10208-1 | Steel Pipes for Pipelines for Combustible Fluids-Pipes of Requirement Class A |

| 23 | EN 10208-2 | Steel Pipes for Pipelines for Combustible Fluids-Pipes of Requirement Class B |

| 24 | EN 10217-1 | Welded Steel Tubes for Pressure Purposes-Non-alloy steel tubes with specified room temperature properties |

| 25 | EN 10217-2 | Welded Steel Tubes for Pressure Purposes-Electric Welded Non-alloy and Alloy Steel Tubes with Specified Elevated Temperature Properties |

| 26 | EN 10217-3 | Welded Steel Tubes for Pressure Purposes-Alloy fine grain steel tubes |

| 27 | EN 10217-4 | Welded Steel Tubes for Pressure Purposes-Electric Welded Non-alloy and Alloy Steel Tubes with Specified Low Temperature Properties |

| 28 | EN 10217-5 | Welded Steel Tubes for Pressure Purposes-Submerged Arc Welded Non-alloy and Alloy Steel Tubes with Specified Elevated Temperature Properties |

| 29 | EN 10217-6 | Welded Steel Tubes for Pressure Purposes-Submerged Arc Welded Non-alloy Steel Tubes with Specified Low Temperature Properties |

| 30 | EN 10224 | Non-alloy Steel Tubes for the Conveyance of Water and Other Aqueous Liquids |

| 31 | EN 10255 | Non-alloy Steel Tubes Suitable for Welding and Threading |

| 32 | EN 10288 | Steel Tubes and Fittings for Onshore and Offshore Pipelines |

| 33 | EN 10296-1 | Welded Circular Steel tubes for Mechanical and General Engineering Purposes-Non-alloy and Alloy Steel Tube |

| 34 | EN 10305-2 | Steel Tubes for Precision Applications-Welded Cold Drawn Tubes |

| 35 | EN 10305-3 | Steel Tubes for Precision Applications-Welded Cold Sized Tubes |

| 36 | EN 10305-6 | Steel Tubes for Precision Applications-Welded Cold Drawn Tubes for Hydraulic and Pneumatic Power Systems |

| 37 | GB/T 13793 | Steel Pipes with a Longitudinal Electric Resistance Weld |

| 38 | GB/T 14980 | Major Diameter Welded Steel Pipes for Low Pressure liquid Service |

| 39 | GB/T 30063 | Longitudinal Submerged Arc Welded Steel Tubes for Structural Purpose |

| 40 | GB/T 3091 | Welded Steel Pipes for Low Pressure Liquid Delivery |

| 41 | GB/T 3092 | Welded Steel Pipe for Low Pressure Service |

| 42 | GB/T 31315 | Cold Drawn or Cold Rolled Precision Weld Steel Tubes for Mechanical Structures |

| 43 | GB/T 31940 | Bi-Metal Composite Corrosion Resistance Steel Pipe for Fluid Transportation |

| 44 | GB/T 32970 | Longitudinal Submerged-Arc Welded Steel Pipe for High Pressure Service at High Temperatures |

| 45 | GB/T 9711 | Steel Pipe for Pipeline Transportation System |

| 46 | JIS G3441 | Alloy Steel Tubes for Machine Purposes |

| 47 | JIS G3442 | Galvanized Steel Pipes for Ordinary Piping |

| 48 | JIS G3443 | Coated Steel Pipes for Water Service |

| 49 | JIS G3444 | Carbon Steel Tubes for General Structure |

| 50 | JIS G3445 | Carbon Steel Tubes for Machine Structure |

| 51 | JIS G3452 | Carbon Steel Pipes for Ordinary Piping |

| 52 | JIS G3454 | Carbon Steel Pipes for Pressure Service |

| 53 | JIS G3456 | Carbon and Alloy Steel Pipes for High Temperature Service |

| 54 | JIS G3460 | Carbon and Alloy Steel Pipes for Low Temperature Service |

| 55 | JIS G3461 | Carbon Steel Boiler and Heat Exchanger Tubes |

| 56 | JIS G3462 | Alloy Steel Boiler and Heat Exchanger Tubes |

| 57 | JIS G3464 | Steel Heat Exchanger Tubes for Low Temperature Service |

| 58 | JIS G3469 | Polyethylene Coated Steel Pipe |

| 59 | JIS G3475 | Carbon Steel Tubes for Building Structure |

| 60 | JIS G7217 | Plain End Welded Precision Steel Tube |

| 61 | DIN 30670 | Polyethylene Coatings on Steel Pipes and Fittings |

| 62 | SY/T 0413 | Polyethylene Caoting for Buried Steel Pipeline |

| 63 | ISO 3183 | Steel Pipe for Pipelines Transportation Systems |

| 64 | API 5L | Specification for Line Pipe |