Seamless Steel Pipe

What is Seamless Steel Pipe?

Seamless steel pipe is made of whole metal and has no joint on the surface. According to the production method, seamless pipe is divided into hot rolled pipe, cold rolled pipe, cold drawn pipe, extruded pipe, pipe jacking, etc.

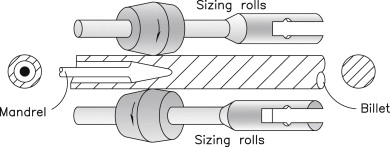

Hot rolled seamless steel pipe is made by automatic continuous rolling machine. In the rolling process, when the temperature reaches the recrystallization temperature, the microstructure and mechanical structure of the steel are changed by controlling different stages such as the initial rolling stage, the finishing rolling stage and the crimping stage, so that it can be deformed into different sizes of pipes.The original casting structure of hot rolled steel pipe (hot rolled seamless pipe) steel plate was destroyed by hot rolling process. The grain of steel material can be refined and the defects of steel plate structure are eliminated. Therefore, hot rolled seamless steel pipe has good mechanical properties and excellent strength. It is widely used to transport fluids, such as oil, natural gas, gas, water and some solid materials, shipbuilding, fertilizer equipment and so on.

Cold-drawn seamless steel pipe produced by drawing, extrusion, perforation and other methods of the whole steel pipe surface without joint steel pipe. It is a circular, square, rectangular steel with hollow section and no joints around it. It is made of steel ingot or solid tube billet through perforation and then made by cold dial.Cold-drawn seamless steel tube can do high precision small batch production. Can be used for mechanical structure, hydraulic equipment of high dimensional precision and good surface finish precision cold drawn seamless pipe.

According to different metal materials, seamless steel pipe can be divided into carbon steel seamless pipe, alloy steel seamless pipe, stainless steel seamless pipe.

According to the cross-section shape, seamless steel pipe can be divided into round and special-shaped, and the special-shaped pipe has many complex shapes, such as square, oval, triangle, hexagon, melon seed, star and winged pipe. The maximum diameter is 650mm and the minimum diameter is 0.3mm.

Seamless steel pipe is mainly used for petroleum geological drilling pipe, cracking pipe for petrochemical industry, boiler pipe, bearing pipe and high-precision structural steel pipe for automobile, tractor and aviation.

| Standard, Application of Seamless Steel Pipe | ||

| S.N. | Standards | Application |

| 1 | ASTM A53 | Seamless and Welded Black and Hot-dipped Galvanized Steel Pipe |

| 2 | ASTM A106 | Seamless Carbon Steel Pipe for High-Temperature Service |

| 3 | ASTM A179 | Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes |

| 4 | ASTM A192 | Seamless Carbon Steel Boiler Tubes for High-Pressure Service |

| 5 | ASTM A209 | Seamless Carbon-Molybdenum Alloy-Steel Boiler and Superheater Tubes |

| 6 | ASTM A210 | Seamless Medium-Carbon Steel Boiler and Superheater Tubes |

| 7 | ASTM A213 | Seamless Ferritic and Austenitic Alloy-Steel Boiler Superheater and Heat-Exchanger Tubes |

| 8 | ASTM A252 | Welded and Seamless Steel Pipe Piles |

| 9 | ASTM A333 | Seamless and Welded Steel Pipe for Low Temperature Service |

| 10 | ASTM A334 | Seamless and Welded Carbon and Alloy Steel Tubes for Low Temperature Service |

| 11 | ASTM A335 | Seamless Ferritic Alloy-Steel Pipe for High Temperature Service |

| 12 | ASTM A500 | Cold Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes |

| 13 | ASTM A501 | Hot Formed Welded and Seamless Carbon Steel Structural Tubing |

| 14 | ASTM A519 | Seamless Carbon and Alloy Steel Mechanical Tubing |

| 15 | ASTM A523 | Plain end Seamless and Electric Resistance Welded Steel Pipe for High Pressure Pipe Type Cable Circuits |

| 16 | ASTM A618 | Hot-Formed Welded and Seamless High-Strength Low-Alloy Structural Tubing |

| 17 | ASTM A714 | High Strength Low Alloy Welded and Seamless Steel Pipe |

| 18 | ASTM A795 | Black and Hot-Dipped Zinc Coated(Galvanized) Welded and Seamless Steel Pipe for Fire Protection USE |

| 19 | EN 10208-1 | Steel Pipes for Pipelines for Combustible Fluids-Pipes of Requirement Class A |

| 20 | EN 10208-2 | Steel Pipes for Pipelines for Combustible Fluids-Pipes of Requirement Class B |

| 21 | EN 10216-1 | Seamless Steel Tubes for Pressure Purposes-Non-alloy Steel Tubes with Specified Room Temperature Properties |

| 22 | EN 10216-2 | Seamless Steel Tubes for Pressure Purposes-Seamless Non-alloy and alloy steel tubes with specified elevated temperature properties |

| 23 | EN 10216-3 | Seamless Steel Tubes for Pressure Purposes-Alloy fine grain steel tubes |

| 24 | EN 10216-4 | Seamless Steel Tubes for Pressure Purposes-Seamless Non-alloy and alloy steel tubes with specified low temperature properties |

| 25 | EN 10224 | Non-alloy Steel Tubes for the Conveyance of Water and Other Aqueous Liquids |

| 26 | EN 10255 | Non-alloy Steel Tubes Suitable for Welding and Threading |

| 27 | EN 10288 | Steel Tubes and Fittings for Onshore and Offshore Pipelines |

| 28 | EN 10297-1 | Seamless Circular Steel Tubes for Mechanical and General Engineering Purposes-Non-alloy and alloy steel tubes |

| 29 | EN 10305-1 | Steel Tubes for Precision Applications-Seamless Cold Drawn Tubes for Precision Applications |

| 30 | EN 10305-4 | Steel Tubes for Precision Applications-Seamless Cold Drawn Tubes for Hydraulic and Pneumatic Power Systems |

| 31 | GB 3087 | Seamless Steel Tube for Low and Medium Pressure Boiler |

| 32 | GB 5310 | Seamless Steel Tube and Pipes for High Pressure Boiler |

| 33 | GB/T 18984 | Seamless Steel Pipes for Low Temperature Service Piping |

| 34 | GB/T 31940 | Bi-Metal Composite Corrosion Resistance Steel Pipe for Fluid Transportation |

| 35 | GB/T 32957 | Cold-drawn or Cold-rolled Precision Inside Diameter Seamless Steel Tubes for Hydraulic and Pneumatic System Service |

| 36 | GB/T 3639 | Seamless Cold-drawn or Cold-rolled Steel Tubes for Precision Applications |

| 37 | GB/T 8162 | Seamless Steel Tube for Structure Purposes |

| 38 | GB/T 8163 | Seamless Steel Tube for Liquid Service |

| 39 | GB/T 9711 | Steel Pipe for Pipeline Transportation System |

| 40 | JIS G3458 | Alloy Steel Pipes for High Temperature Sevice |

| 41 | JIS G3441 | Alloy Steel Tubes for Machine Purposes |

| 42 | JIS G3444 | Carbon Steel Tubes for General Structure |

| 43 | JIS G3445 | Carbon Steel Tubes for Machine Structure |

| 44 | JIS G3454 | Carbon Steel Pipes for Pressure Service |

| 45 | JIS G3455 | Carbon Steel Pipes for High Pressure Service |

| 46 | JIS G3456 | Carbon and Alloy Steel Pipes for High Temperature Service |

| 47 | JIS G3460 | Carbon and Alloy Steel Pipes for Low Temperature Service |

| 48 | JIS G3461 | Carbon Steel Boiler and Heat Exchanger Tubes |

| 49 | JIS G3462 | Alloy Steel Boiler and Heat Exchanger Tubes |

| 50 | JIS G3464 | Steel Heat Exchanger Tubes for Low Temperature Service |

| 51 | JIS G3469 | Polyethylene Coated Steel Pipe |

| 52 | JIS G3475 | Carbon Steel Tubes for Building Structure |

| 53 | JIS G7216 | Plain End Seamless Precision Steel Tube |

| 54 | DIN 30670 | Polyethylene Coating on Steel Pipes and Fittings |

| 55 | SY/T 0413 | Polyethylene Coating for Buried Steel Pipeline |

| 56 | API 5L | Specification for Line Pipe |

| 57 | ISO 3183 | Steel Pipe for Pipelines Transportation Systems |